After looking for the ideal location to promote and sell its highly innovative 3D printers on the European market, Russian start-up Anisoprint moved its headquarters to Luxembourg in 2018. In 2020, the decision followed to move the manufacturing of its printers here as well.

Luxembourg manufacturing

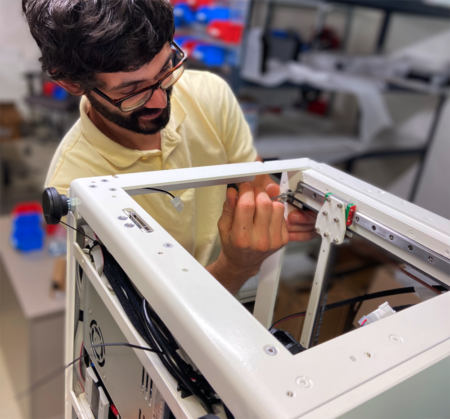

Initially relying on contract manufacturing, the company realised that this required considerable work to manage quality control and deadlines. The outbreak of the COVID-19 pandemic and the related supply chain disruptions prompted the decision to start producing the printers in-house.

Initially relying on contract manufacturing, the company realised that this required considerable work to manage quality control and deadlines. The outbreak of the COVID-19 pandemic and the related supply chain disruptions prompted the decision to start producing the printers in-house.

After careful consideration of every option and location, we made the decision to set up our own production facility in Luxembourg.

“Since the first launch of our products back in 2018, we constantly looked for an ideal manufacturing solution, trying to balance between the quality, customer proximity, logistics and lead times, predictability and cost,” explains CEO Fedor Antonov. “After careful consideration of every option and location, we made the decision to set up our own production facility in Luxembourg, next to our head office.”

As reasons for this decision, Anisoprint notably highlights the country’s central location in Europe, its logistics hub and its convenient tax regime for export production. “We stopped at nothing to find the best solution for a manufacturing facility and find professionals who are willing to contribute their expertise for making the quality of the machines even higher and live up to the expectations of our customers,” underlines Dr Antonov.

“Made in Luxembourg” label

The most commonly used material for 3D printing, plastics, often does not have the properties required for industrially produced functional parts. Anisoprint has developed 3D printers that allow for the manufacturing of continuous fibre-reinforced plastic parts able to replace metal ones in fields such as aerospace and engineering. Its patented Continuous Fibre Coextrusion technology can be used to produce lattice structures that are lighter, stronger and cheaper than their metal equivalents.

Adding in-house production to its activities, Anisoprint has now also received a “Made in Luxembourg” label from the Chamber of Commerce. The label is awarded to companies that comply with all local regulations and provide high-quality products or services to their customers. “We are proud to receive a ‘Made in Luxembourg’ label for the first batch of Composer 3D-printers manufactured in our new facilities,” Dr Antonov concludes.